Overview Of PET And PP Plastic

PET and PP are two of the most widely used plastics in the world, each with its own unique set of properties and applications.

-

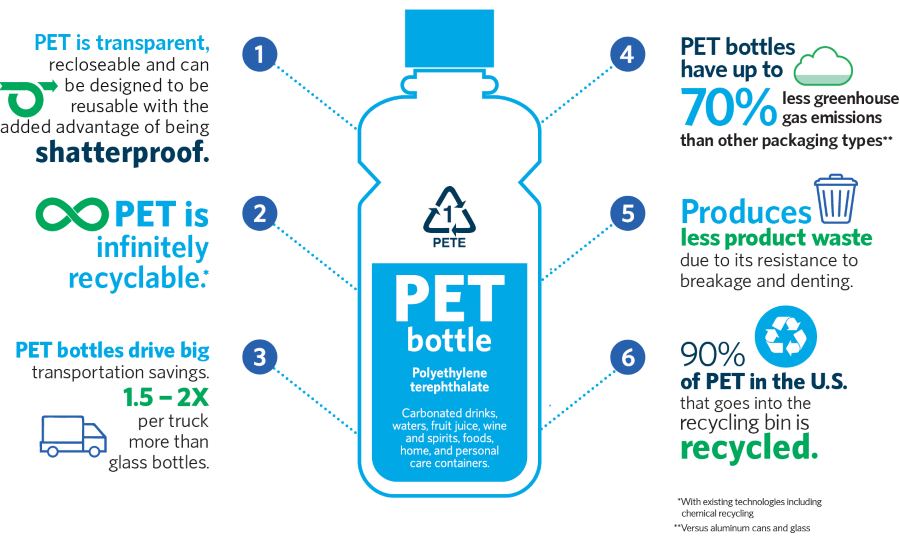

PET (Polyethylene Terephthalate):

- A thermoplastic polyester known for its high strength, clarity, and resistance to chemicals.

- Commonly used in food and beverage packaging (bottles, containers), textiles (fibers, fabrics), and engineering applications.

- A thermoplastic polyester known for its high strength, clarity, and resistance to chemicals.

-

PP (Polypropylene):

- A versatile thermoplastic known for its high strength, stiffness, and resistance to heat and chemicals.

- Widely used in packaging (containers, lids, wraps), automotive parts, textiles (ropes, carpets), and medical devices.

- A versatile thermoplastic known for its high strength, stiffness, and resistance to heat and chemicals.

PET vs. PP: Comparing Properties

| Property | PET | PP |

|---|---|---|

| Strength | High tensile strength, good impact resistance | High tensile strength, good impact resistance, high stiffness |

| Clarity | High clarity, transparent | Can be translucent or opaque |

| Heat Resistance | Good heat resistance, can withstand hot filling | Excellent heat resistance, high melting point |

| Chemical Resistance | Good resistance to most chemicals, except strong alkalis | Good resistance to most chemicals, including many acids and bases |

| Flexibility | Can be rigid or flexible depending on the grade | Generally more rigid than PET, but can be made flexible |

| Density | Relatively low density | Low density, one of the lightest commercial plastics |

| Cost | Moderate cost | Relatively low cost |

| Recyclability | Highly recyclable | Recyclable, but recycling rates can vary |

PET vs. PP: Pros & Cons

PET Plastic

-

Pros:

- High clarity and aesthetics

- Good barrier properties against gases and moisture

- Lightweight and durable

- Widely recyclable

- Suitable for food contact applications

-

Cons:

- Can be susceptible to stress cracking

- Not as heat resistant as PP

- May not be suitable for all hot filling applications

PP Plastic

-

Pros:

- Excellent heat resistance

- High stiffness and strength

- Good chemical resistance

- Lightweight and durable

- Versatile processing options

-

Cons:

- Lower clarity than PET

- May not be as good as PET for gas and moisture barrier applications

- Can be more difficult to recycle than PET in some cases

PET vs. PP: Comparing Applications

PET Plastic

- Food and Beverage: Bottles for carbonated drinks, water, juices, and other beverages; containers for food products; trays and clamshells for ready-to-eat meals.

- Textiles: Clothing, carpets, upholstery, industrial fabrics.

- Packaging: Blister packs, trays, and containers for various consumer goods.

- Medical: Medical devices, drug delivery systems.

- Automotive: Interior components, such as headliners and door panels.

PP Plastic

- Packaging: Containers, lids, wraps, and films for food and non-food products.

- Automotive: Bumpers, dashboards, interior trim, and other components.

- Textiles: Ropes, carpets, and non-woven fabrics.

- Medical: Medical devices, syringes, and containers.

- Consumer Goods: Toys, appliances, and other durable goods.

Which Plastic Should You Choose?

The choice between PET and PP depends on the specific requirements of the application, such as:

- Clarity and aesthetics: If high clarity is essential, PET is generally preferred.

- Heat resistance: If the application requires high heat resistance, PP is a better choice.

- Chemical resistance: Both PET and PP offer good chemical resistance, but PP may be more suitable for certain applications.

- Processing requirements: The chosen plastic should be compatible with the available processing equipment.

- Environmental considerations: The recyclability and environmental impact of each plastic should be considered.